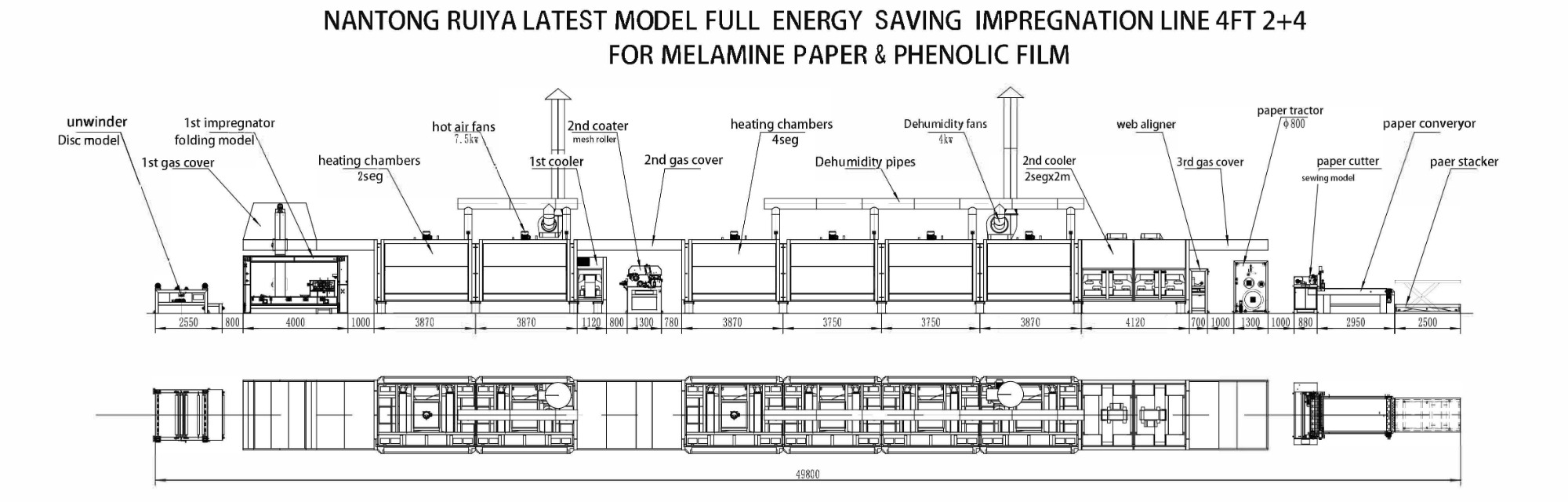

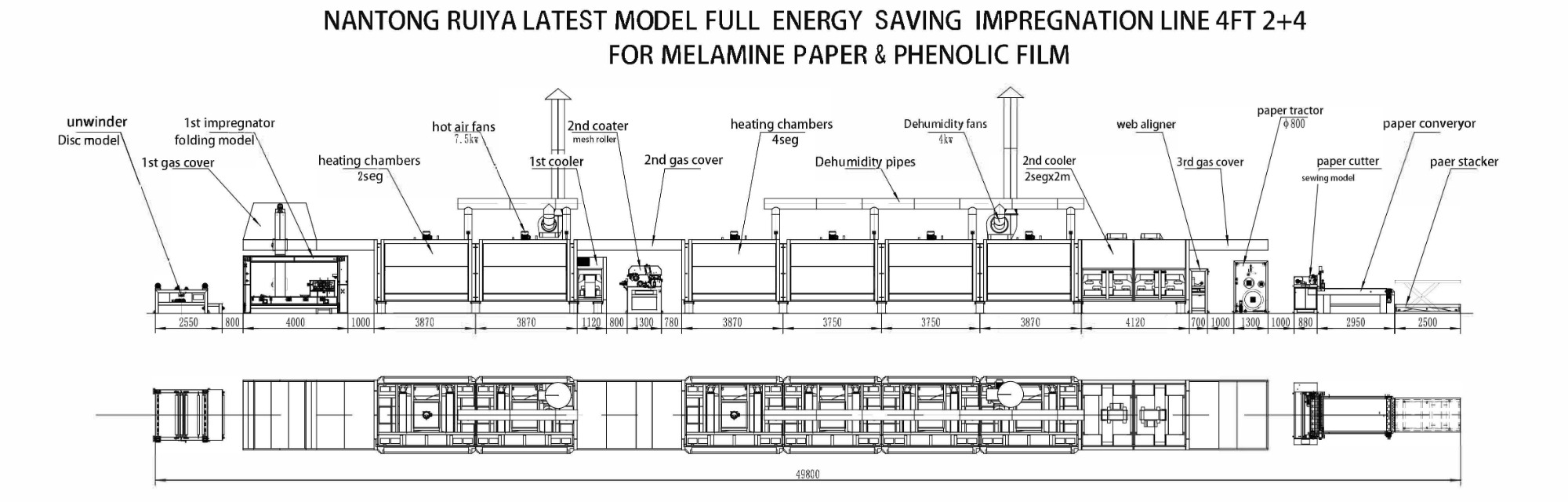

NTRY Impregnation line for melamine paper production line layout for reference:

NTRY melamine impregnation line Basic Parameter:

1, Main raw Material: 60-150g/m

2 pre-printed wood grain decor paper or solid color paper;

2, Working width: Max 1350mm, compatible with 1220mm;

3, Mechanical speed: 0-60m/min;

4, Working speed: 20-25m/min depends on raw paper gsm and glue property of permeability;

5, resin: MF, UF, PF;

6, Glue pickup for MDF board, 135%, operating pickup control: 33~150%;

7, Volatilization content: 6.5-7.5%;

8, Heating source: inlet temperature over 200

0C thermal oil or over-heating boiler steam water;

9, Heating capacity: 600,000kcal/hour for 4ft 2+4 two step model;

Impregnation line for Melamine Paper Machine Special Parts included:

PLC unit: Siemens/Mitsubishi

Adapter/contactor: Schneider or Siemens

Motor: China Famous Brand, easier shifting maintains

Pneumatic: Festo

Touch Screen: Siemens or Mitsubish

We supply 4ft 5ft 6ft 7ft 8ft impregantion line for melamine paper production line, high efficiency and energy saving, friendly HMI, welcome your kind inquiry.